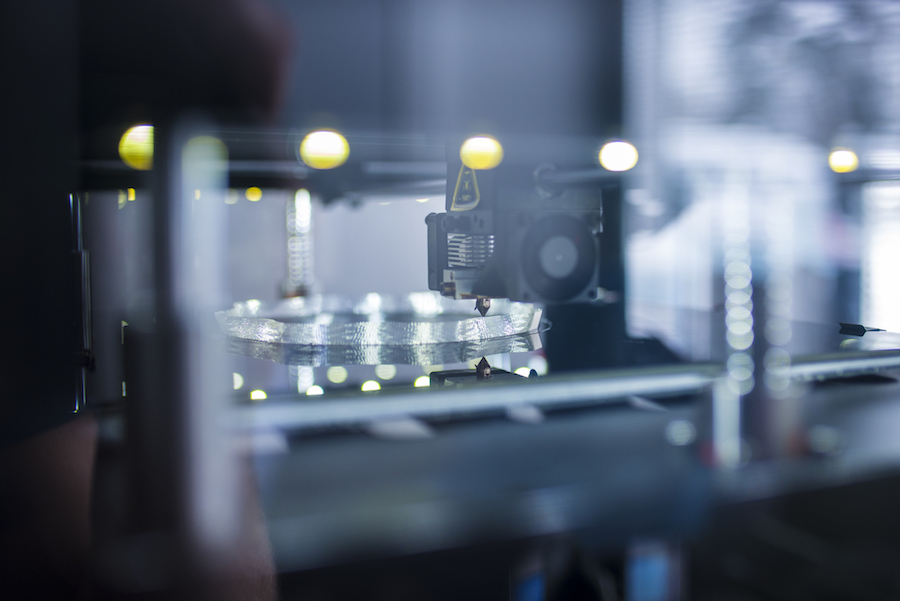

Metal additive manufacturing is the process by which metal parts are joined or solidified from a feedstock. Also known as 3D printing, metal additive manufacturing machines can use a variety of processes to build parts.

Unlike subtractive manufacturing which removes material, additive manufacturing adds material through different processes reducing waste and allowing for faster production than traditional subtractive techniques.

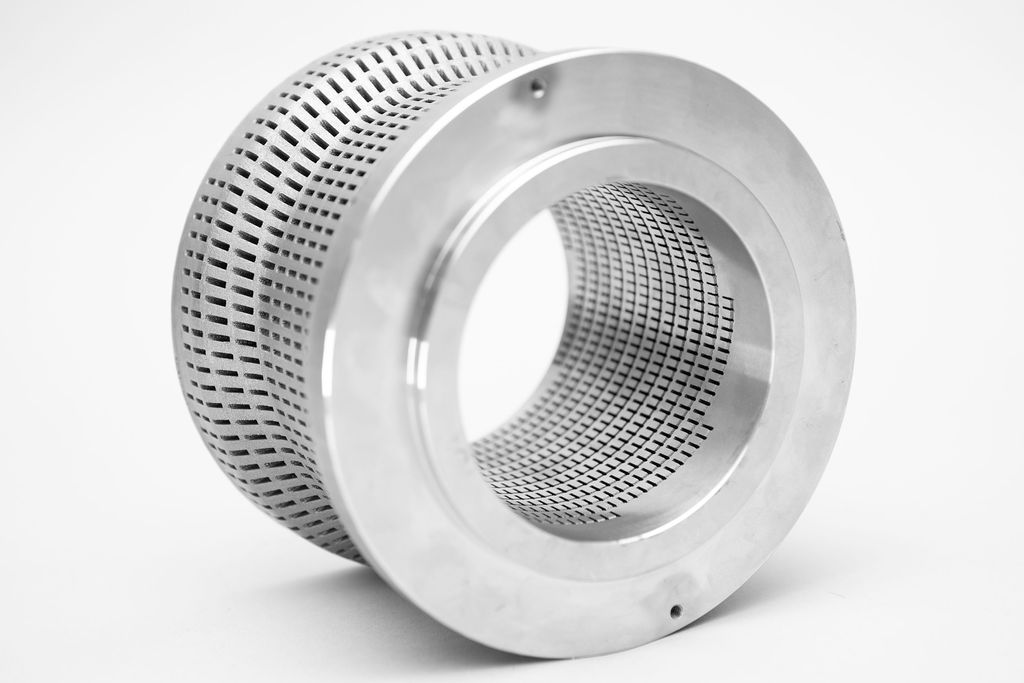

Parts are created directly from CAD files without manual toolpath setup and can be designed with internal features or complex geometries that would not be possible with subtractive manufacturing processes. Additive manufacturing reduces design risk and provides efficiencies for the manufacturing process.

As an active member of America Makes, the National Additive Manufacturing Innovation Institute, our company is associated with the nation’s leading collaborative partner in 3D printing technology research, discovery, creation, and innovation. Our membership in America Makes also presents IMI with unique opportunities to collaborate with other member organizations in an extensive range of industries to innovate and accelerate the adoption of additive manufacturing.

In our active role in the development of additive manufacturing technologies, IMI is involved in the development and testing of materials, parts qualification, standards development, machine agnostic printing, and digital security. We are also gaining valuable insight into new target sectors such as pharmaceutical and medical.

An important prerequisite for the success of this project was the participation of partners representing the complete value chain. In Additive Manufacturing, the collaboration of multiple partners with expertise in specific processes and activities, is essential. The partners collaborated in two coherent and seamlessly aligned programs.

First of all, to develop a guideline for the qualification of additively manufactured parts managed by DNV-GL. The final guideline provides a framework to ensure that metal spare parts and components, produced via Wire Arc Additive Manufacturing (WAAM) and Laser-based Powder Bed Fusion (LPBF), are according to specifications…